With its Orchard One project in Wyoming, Spiritus thinks it can capture carbon from the air for less than $100 per ton. Pretty much every startup that’s building machines to suck carbon dioxide from the atmosphere and stash it underground has claimed it will be able to get its costs down to less than $100 per ton — eventually.

But a new contender in the race, a San Francisco-based company called Spiritus, is making a compelling case that it could get there faster. On Tuesday, Spiritus announced plans to build its first direct air capture, or “DAC” project in central Wyoming, nicknamed Orchard One. The company will start small but ultimately wants to expand the facility to capture 2 million tons of CO2 per year.

Achieving that scale at the sub-$100 price point would be game-changing for direct air capture, which is still far too expensive to be a viable climate solution. Most companies in the field are cagey about revealing their current costs, but the industry-average price is believed to be between $600 and $1,000 per ton.

So what makes Spiritus different? Here are three reasons we’ll be keeping an eye on the company.

Spiritus is making use of a potentially … fruitful new material

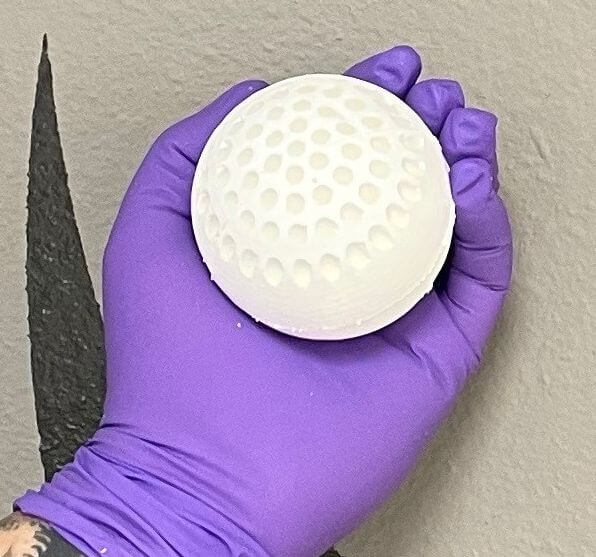

Spiritus’ project will not look anything like the industrial-style shipping containers full of fans that have become the defining form factor for DAC plants. The company’s central innovation is a squishy white ball that founder Charles Cadieu describes as an artificial lung.

“While it looks kind of simple, it’s actually a breakthrough material that has an incredible amount of surface area,” he told me over Zoom, while holding one up and squeezing it like a stress relief toy. “And it has holes all over it that allow the CO2 to go right inside.” Though it’s about the size of a tennis ball, its branch-like interior structure has a surface area equivalent to a tennis court, he said.

The ball is made of a proprietary material that selectively attracts CO2 molecules. As air wafts through it, CO2 sticks to its interior surfaces like a magnet. Spiritus will manufacture millions of these balls, lay them out on trays, and stack the trays on tree-like rigs — hence the name Orchard One. Concept images depict a small colony of cylindrical structures that will house the trays, almost like miniature Wilco towers, sprouting up amid the Wyoming sagebrush.

After a few hours exposed to the elements, the balls, which Spiritus prefers to call “fruits,” will be full of carbon. The company will then transfer them to a separate chamber and apply heat, causing them to expel the CO2. That stream of carbon will be compressed and delivered to an underground CO2 storage well, while the fruits will be returned to their towers to live the same day over and over again.

It requires a lot less energy

Though the concept is somewhat whimsical, the company is making serious claims about its cost and performance. The biggest expenses for direct air capture projects are materials and energy, and Spiritus has made significant improvements on both fronts. Cadieu told me they can manufacture their sorbent for a tenth of the cost of other, “state of the art sorbents that are out there today,” and that “furthermore, it’s 10 times as effective” at capturing carbon. In other words, Spiritus claims it can capture more carbon from the air at a time, using fewer, cheaper materials than other methods.

Since the capture part of the process is passive, the company doesn’t need to use energy-intensive fans to filter the air. Also, the temperature required for the second step, where heat is applied to the balls to release the CO2, is lower than 212 degrees Fahrenheit — low enough to be generated using electricity. Cadieu said Spiritus plans to procure energy from renewable sources so that the entire process has net-negative greenhouse gas emissions.

Spiritus isn’t the only company with a low-cost sorbent and passive capture method. Notably, the DAC process pioneered by Heirloom, which opened its first commercial-scale plant in California last year, shares those features, but it requires much higher temperatures — 1,650 degree Fahrenheit — to isolate the captured carbon.

Though Spiritus still has to prove this all works as promised in the real world, the company has earned an early vote of confidence from Frontier, the coalition of tech companies with a $1 billion fund to help carbon removal scale. Last year, Frontier paid Spiritus $500,000 to buy its first 713 removal credits, each of which represents a ton of carbon that will be permanently sequestered underground. (The money is more of a development grant than anything indicative of the company’s costs.)

“We look for companies that learn and iterate quickly, and we were impressed by what we saw from Spiritus when they applied,” Joanna Klitzke, the procurement and ecosystem strategy lead at Frontier, told me. “And actually, since then, the team has made really strong improvements and steady progress on both their sorbent and their process performance.”

According to the company’s application for funding from Frontier, Spiritus estimates that for the first phase of Orchard One — when the project is capturing less than 2,000 tons per year — its levelized cost per ton of carbon will be about $149, not including the cost of burying the carbon underground. By phase two, at a scale of about 500,000 tons per year, it expects to get that cost down to less than $100. And by phase three, at the full scale of 2 million tons per year, it expects to achieve sub-$75 capture.

Cadieu told me the company is already in talks with large buyers to purchase carbon removal from Orchard One for “far less” than the per-ton price Frontier paid.

It’s following the three rules of real estate: location, location, location

Spiritus doesn’t expect to have phase one of the project up and running until 2026. But it already has a running start. The land lease is locked down, the underground pore space where the company will inject the captured carbon has been identified, and a monitoring well is already scheduled to be drilled — according to its Frontier application.

Wyoming has proved to be a relatively welcoming place for this emerging industry. Orchard One is joining another direct air capture plant already under development in the southwest part of the state called Project Bison. Cadieu gave three reasons the project landed there: There’s a local workforce with relevant experience from the oil and gas industry, the state has the ideal geology to trap the captured carbon underground, and Wyoming has been at the forefront of developing clear regulations for carbon sequestration. It was one of the first states to gain authorization from the Environmental Protection Agency to permit carbon storage wells, and as of December had already permitted three. Another advantage in Wyoming is abundant renewable energy from wind farms.

Spiritus has yet to reveal exactly where in Wyoming Orchard One will be built, but Cadieu told me he has been in close contact with officials at the town, county, and state levels, and that the reception has been enthusiastic. He said the project will create “hundreds of jobs during construction” and “many dozens of jobs” when the facility is operating, and that the company will deliver a portion of its profits back into the community.